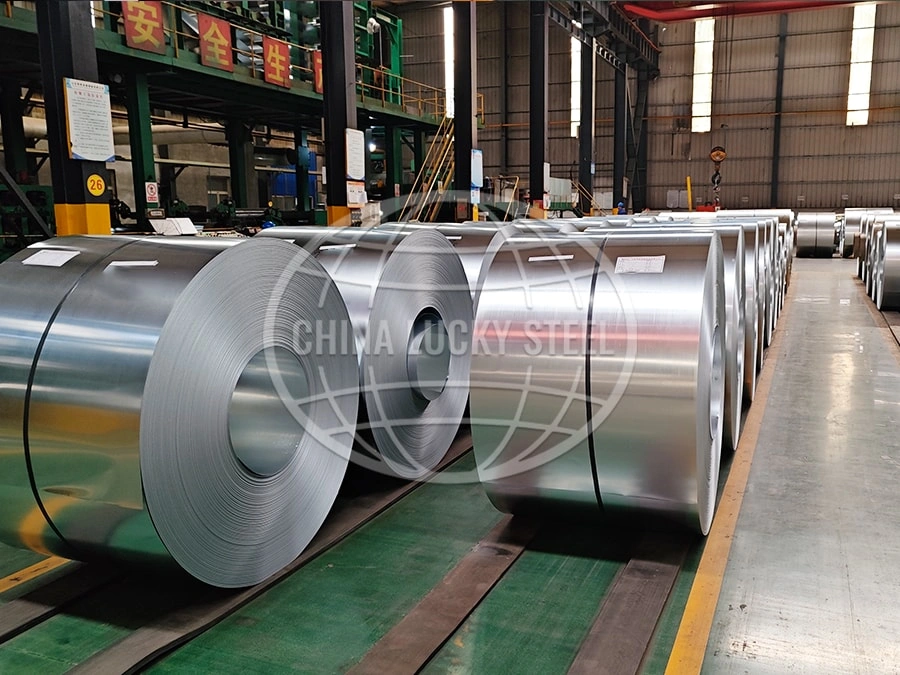

According to the different manufacturing processes and uses, steel coils can be divided into several types, such as cold-rolled steel coils, hot-rolled steel coils, hot-dip galvanized steel coils, cold-galvanized steel coils and color-coated steel coils.

1. Cold-rolled steel coil: The production process of cold-rolled steel coil is relatively simple and the cost is low. It is widely used in the fields of steel structure, machinery manufacturing and construction.

2. Hot-rolled steel coil: Hot-rolled steel coil can adjust the performance of steel by controlling the rolling temperature, which is suitable for the manufacture of automobiles, machinery manufacturing and construction.

3. Hot-dip galvanized steel coil: By plating zinc metal on the surface of the steel coil, the corrosion resistance and strength of the steel coil can be improved, which is commonly used in the fields of construction and electricity.

4. Cold-galvanized steel coil: Compared with hot-dip galvanized steel coil, cold-galvanized is more environmentally friendly, but has less corrosion resistance and strength. It is mostly used in household appliances, body parts and construction fields.

5. Color coated steel coil: Color coated steel coil is processed by spraying paint on the surface of the steel coil, which is commonly used in construction, electrical appliances, automobiles and other fields.